UVC: a new generation of disinfection and sterilization technology

发布时间:2022-03-24 16:46

来源:萤光创新

UVC: the first choice of healthy light source

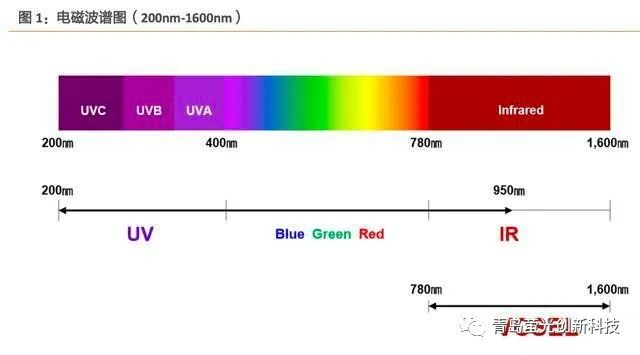

UV (ultraviolet) refers to the electromagnetic wave with the wavelength between 10nm-400nm, that is, ultraviolet. According to the wavelength, ultraviolet can be divided into long wave ultraviolet (UVA), medium wave ultraviolet (UVB) and short wave ultraviolet (UVC). The wavelengths are 320-400nm, 280-320nm and 100-280nm respectively.

Compared with UVA and UVB, UVC has little impact on human body.

UVA has strong penetration ability and can reach the dermis of the skin. On the one hand, UVA can directly convert the melanin precursor in the skin into melanin and make the skin blacken rapidly; On the other hand, UVA will make the skin produce living oxygen free radicals, which will bring great oxidative pressure to the skin for a long time, and lead to the damage of collagen, elastin and DNA in the skin, resulting in skin aging, loss of elasticity and wrinkles. UVB mainly acts on the surface of the skin. UVB will activate tyrosinase in melanocytes in the basal layer of the epidermis to synthesize melanin. After melanin is formed, it will gradually migrate to the outermost layer, causing skin blackening, erythema, or sunburn. In short, UVA and UVB are harmful to human skin, while UVC is less harmful to human body than UVA and UVB. This is because the wavelength of UVC is very short, the penetration is very low, and it can not go deep into the skin epidermis.

UVC has strong sterilization and disinfection effect and inactivates the virus more thoroughly.

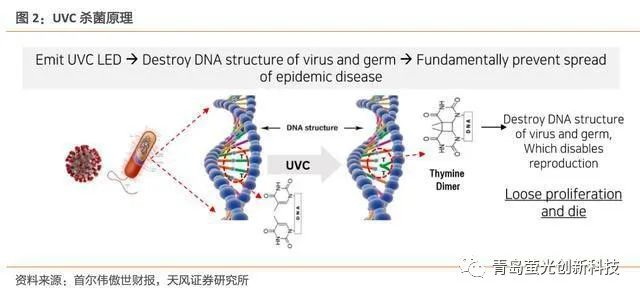

People often use the way of sunlight to eliminate the bacteria on food, so as to achieve the function of disinfection and quality assurance. According to the principle of sunlight disinfection, artificial ultraviolet technology has been gradually developed. Ultraviolet is a kind of mutagen, which can kill microorganisms by damaging the radiation of microorganisms and destroying the function of nucleic acid, so as to achieve the purpose of disinfection. In a specific wavelength range (mainly UVC) and high enough dose, ultraviolet can cause abnormal chemical bonds between adjacent pyrimidine molecules of DNA or RNA in microbial cells such as bacteria and viruses, hinder the replication of DNA or RNA, and cause microbial cell death. The sterilization effect of UVC is achieved through the deep ultraviolet wavelength of semiconductor.

Compared with chemical sterilization and disinfection, ultraviolet has the advantage of high sterilization efficiency, inactivation is generally completed in a few seconds, and no other chemical pollutants are produced. In front-line medical and health institutions, it is also an important sterilization and disinfection equipment. Because the shorter the wavelength and the higher the frequency of ultraviolet, the higher the energy contained. Therefore, compared with UVA and UVB, UVC has stronger sterilization ability and faster effect.

UVC is the ultraviolet ray with the best sterilization effect in nature, but it is very difficult for people to directly use UVC in sunlight. This is because UVC has been absorbed and scattered by the ozone layer in the atmosphere due to its short wavelength and cannot reach the ground. Therefore, artificial UVC becomes particularly important.

UVC has obvious advantages: miniaturization, no toxicity and convenient use

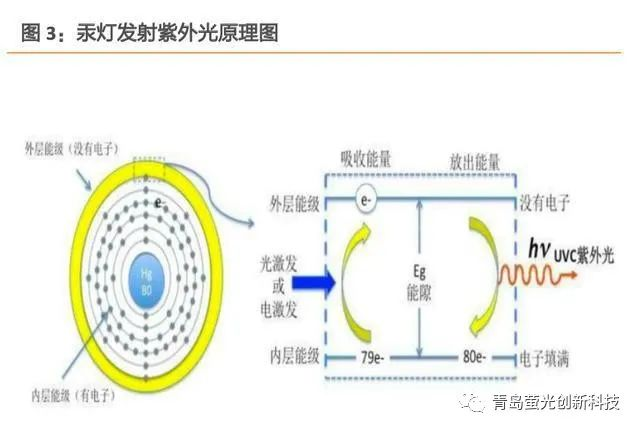

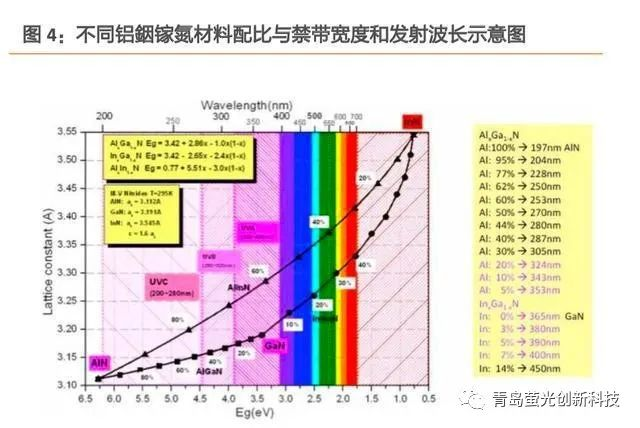

At present, there are mainly two kinds of UV light sources for sterilization: traditional mercury lamp and UV LED. Mercury lamp is the most mainstream product of ultraviolet disinfection, curing and exposure. The principle of this lamp is very simple. The high-energy electrons emitted by the cathode ray tube excite the atoms of mercury vapor into an excited state, and the excited electrons return to the ground state to emit ultraviolet light. UV LED is a light source that uses the semiconductor luminescence principle to manufacture UV band. By using the ratio change of aluminum indium gallium nitrogen material, it can make UV and visible light in different bands.

Compared with UV LED, traditional mercury lamp has some disadvantages: large size; The start-up time is long, and it is impossible to start and use immediately; Fragile and short service life; Highly toxic, it will cause mercury leakage after rupture, pollute the environment and seriously endanger human health. Compared with many disadvantages of traditional mercury lamps, deep ultraviolet semiconductor has obvious policy and technical advantages. Among various sterilization and disinfection methods, only deep ultraviolet semiconductor has excellent characteristics such as energy saving, ready to use, space saving, non-toxic and harmless, long service life, no pungent smell and so on. Therefore, deep UV semiconductor has become the best choice for a new environmental friendly and efficient UV light source.

The improvement direction of UVC process is clear, and the technical problems are constantly broken through

The process of deep UV semiconductor is roughly the same as that of ordinary led, but due to the different luminous materials of UV LED, the selected luminous materials and packaging forms will be different. UVC semiconductor chip can be divided into substrate and epitaxial layer: the substrate usually uses the sapphire substrate used by blue LED chip. The epitaxial layer includes AlN template layer, n-type AlGaN layer, multi quantum well light-emitting layer, electron barrier layer and p-type GaN contact layer. In the chip process, the n-type contact layer is leaked through photolithography and etching, and the n-type and p-type form ohmic contact with the electrode through evaporation and alloy. Then, the small core particles are sorted through thinning and splitting, and inverted onto the insulated silicon wafer.

Since the emission spectral wavelength of deep UV semiconductor is usually less than 300nm, the selection of packaging mode will affect the light output efficiency, and lens packaging and non lens packaging have a great impact on the light output of UV LED. Therefore, there are high requirements for packaging in the manufacturing process. The commonly used packaging forms include flip flip flip, cob and modular packaging.

After more than 10 years of research and development, the ultraviolet quantum efficiency of deep UV semiconductors below 280 nm has exceeded 5%, the corresponding luminous power is greater than 5 MW, and the lifetime is 5000 H. The improvement of power promotes the development of application fields, but compared with the blue LED with very mature technology, UVC semiconductor has three main problems: difficult chip epitaxial growth, easy aging of packaging materials and low light extraction efficiency. Therefore, the focus of its development is to overcome these weaknesses and promote the improvement of relevant technologies.

Qingdao fluorescent Innovation Technology Co., Ltd. has a professional postdoctoral team, focusing on the research of ultraviolet sterilization application. After years of deep cultivation in the ultraviolet industry, the company has obtained a number of national invention and utility model patents. At present, a number of sterilization module products have been put into the market. For more details, please visit the company's website at www.qdyingguang.com Com contact the company for the official account of WeChat.

Keywords: 220nm, 230nm, 235nm, 240nm, 245nm, 250nm, 255nm, 260nm, 265nm, 270nm, 275nm, 280nm, 285nm, 290nm, 295nm, 300nm, 305nm, 310nm, 315nm, 320nm, 330nm, 340nm, 365nm, 395nm, 405nm, to39, uvworks, uvworks, UVC works, UVC EOS, UV LED, UVA led, UVB led, UV LED, deep UV LED, UV sterilization, UV disinfection, UV sterilization Ultraviolet disinfection scheme, sterilization module, water purifier sterilization, terminal sterilization faucet, static water sterilization component, flowing water sterilization component, ultraviolet sterilization water purifier, sterilization faucet, toothbrush sterilization, water cup sterilization, surface sterilization, water sterilization, air sterilization and phototherapy